In marine and industrial applications, compressors play a critical role in maintaining operational efficiency and reliability. Selecting high-quality compressor spare parts is essential to ensure optimal performance, prevent costly downtime, and extend the lifespan of your equipment. This guide explores the key considerations for choosing compressor spare parts, highlights leading brands, and provides maintenance tips to help you maximize your system’s potential.

Why Quality Matters in Compressor Spare Parts

Compressors operate under demanding conditions, often exposed to harsh environments, fluctuating pressures, and continuous workloads. Using substandard or incompatible spare parts can lead to premature wear, reduced efficiency, and even catastrophic failures. Therefore, prioritizing genuine and certified components is crucial for:

Maintaining system integrity

Ensuring safety standards

Reducing unplanned maintenance costs

Enhancing energy efficiency

Key Compressor Spare Parts and Their Roles

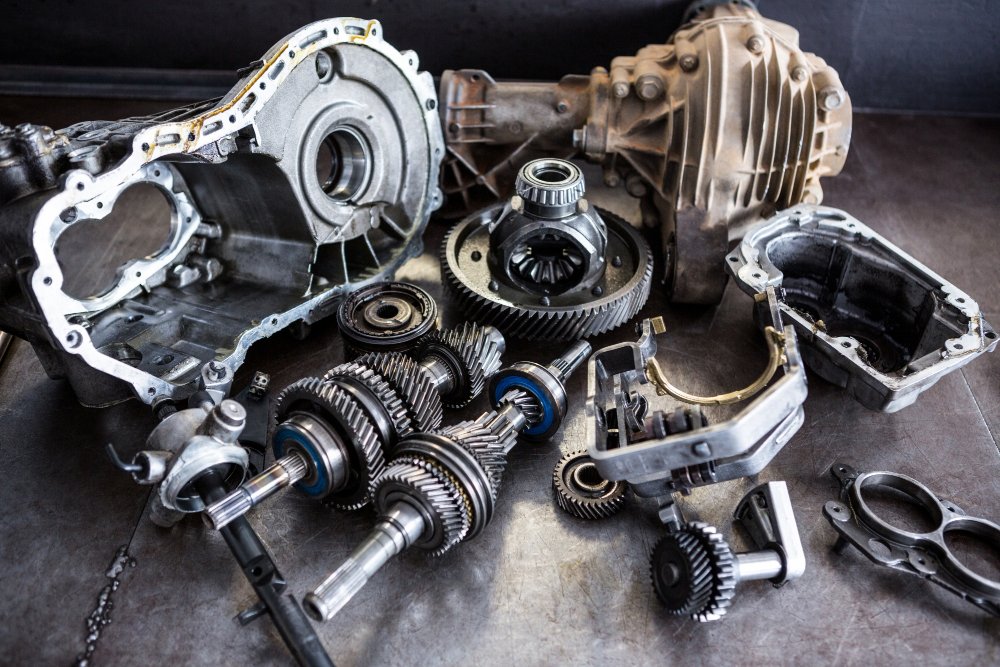

Understanding the function of essential compressor parts helps in accurate selection and troubleshooting. Common critical spare parts include:

Mechanical Seals: Prevent leakage of compressed gases and fluids. High-quality seals reduce wear and enhance reliability.

Bearings (Ball, Roller, Axial): Support rotating shafts and minimize friction. OEM bearings ensure smooth operation and longevity.

Valves (Inlet/Discharge): Regulate airflow; precise valves improve compressor efficiency and performance.

Pistons and Rings: Core moving components that require durability and tight tolerances for efficient compression cycles.

Couplings and Belts: Transmit power; robust couplings prevent misalignment and mechanical stress.

Leading Brands in Compressor Spare Parts

Working with trusted manufacturers guarantees quality and compatibility. Some globally recognized brands in compressor components are:

Atlas Copco: Renowned for innovative compressor technologies and high-grade spare parts.

Sauer: Offers durable seals, valves, and other critical components optimized for heavy-duty applications.

Mitsubishi: Provides precision-engineered compressor parts designed for marine and industrial usage.

Sperre: Specialized in screw compressors with reliable spare part options ensuring performance consistency.

Tips for Selecting Compressor Spare Parts

Verify Compatibility: Always cross-check part numbers and specifications with your compressor model.

Prefer OEM or Certified Parts: Avoid generic or counterfeit components which may compromise safety and performance.

Consider Operating Conditions: Choose parts suited for your compressor’s pressure, temperature, and environmental demands.

Stock Essential Spares: Maintain an inventory of frequently replaced parts to minimize downtime.

Maintenance Best Practices for Compressor Components

Regular maintenance prolongs the life of compressor parts and keeps systems running smoothly:

Routine Inspection: Check seals, bearings, and valves for wear or damage. Early detection prevents bigger failures.

Lubrication: Use manufacturer-recommended lubricants to reduce friction and heat buildup.

Cleaning: Keep components like filters and valves free from contaminants to maintain airflow and efficiency.

Timely Replacement: Replace worn parts promptly based on service intervals or operational signs.

Conclusion

Choosing the right compressor spare parts and maintaining them properly is a vital investment for any marine or industrial operation. By relying on genuine components from trusted brands and following rigorous maintenance protocols, you ensure your compressor delivers peak performance, energy efficiency, and reliability over the long term.