Marine systems rely on a complex network of interconnected components, each responsible for ensuring safe, efficient, and continuous vessel operations. While engines, separators, and pumps often take the spotlight, certain smaller components play equally significant roles. Among these, water valve blocks and transducers stand out as two of the most critical yet frequently underestimated parts of modern ships.

At Maridec, we emphasize not only the availability of spare parts but also the knowledge behind their importance. Understanding how water valve blocks and transducers function, why they matter, and how they impact operational efficiency helps shipowners and operators make informed decisions for long-term performance and compliance

The Importance of Supporting Components in Marine Engineering

Large-scale marine equipment—such as separators, compressors, and pumps—cannot perform optimally without the precise control and monitoring provided by smaller supporting components. Water valve blocks regulate water flow through vital circuits, while transducers provide the data necessary for real-time adjustments.

Neglecting these components often leads to:

- Reduced energy efficiency

- Unexpected equipment downtime

- Higher maintenance costs

- Non-compliance with IMO and MARPOL standards

Therefore, maintaining these systems is not just a technical necessity but also an operational and regulatory priority.

What Are Water Valve Blocks?

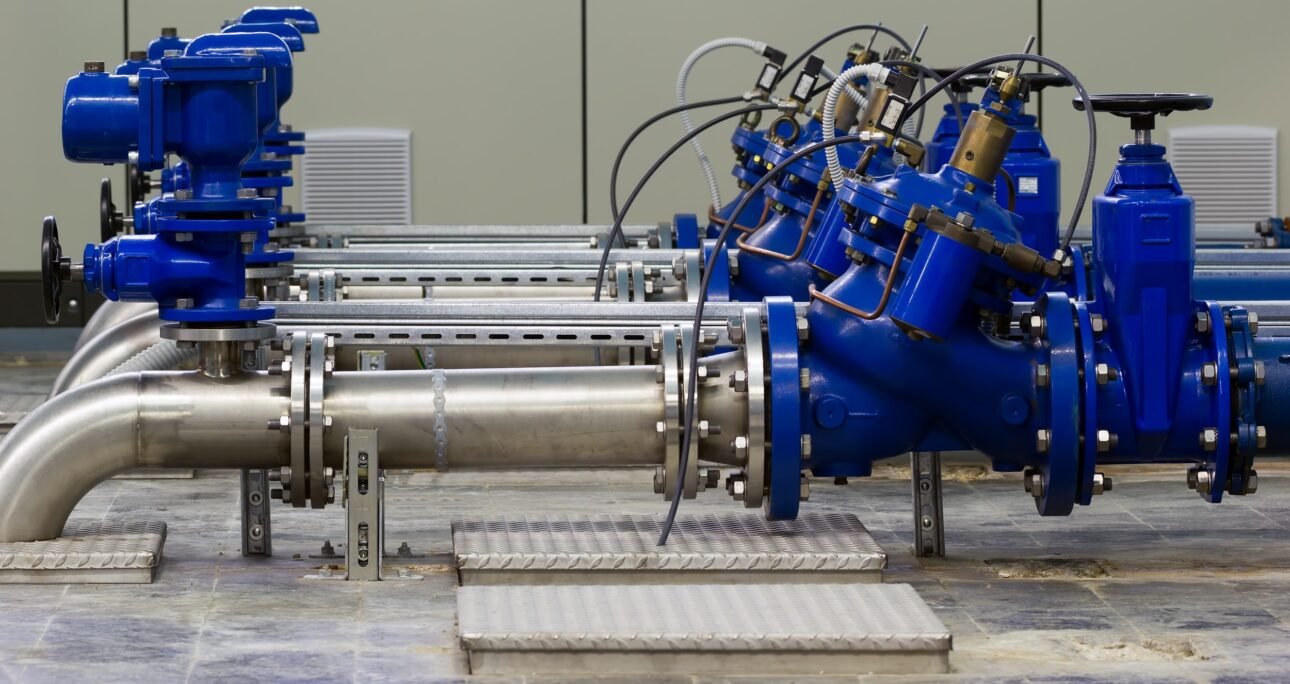

A water valve block is a compact hydraulic unit designed to manage and regulate the distribution of water across different circuits within a marine system. They integrate multiple valves into a single housing, creating a centralized hub for water flow control.

These blocks are particularly essential in:

- Cooling Systems – regulating engine and auxiliary machinery cooling water

- Separator Systems – managing fresh and backflush water in purification processes

- Fuel Treatment Units – ensuring stable operation by controlling water input and discharge

- Ballast Systems – supporting the safe intake and discharge of ballast water

Key Advantages of Water Valve Blocks

Centralized Fluid Management

By consolidating multiple valves into a single block, system design becomes more compact and efficient. This reduces potential leak points and improves ease of maintenance.

Enhanced Operational Safety

Reliable valve blocks prevent uncontrolled leaks or failures, safeguarding crew and equipment.

Simplified Maintenance

Pre-assembled units allow for quick replacement, minimizing downtime during maintenance intervals.

Longevity and Durability

High-quality water valve blocks are built from corrosion-resistant materials, ensuring extended service life even under harsh marine conditions.

The Role of Transducers in Marine Systems

What Are Transducers?

A transducer is an electronic device that converts physical measurements into readable signals for monitoring and control. In marine applications, transducers are indispensable for real-time data acquisition, ensuring equipment operates within safe parameters.

Types of Marine Transducers and Their Applications

Pressure Transducers

Measure hydraulic and pneumatic pressure levels, ensuring pumps and separators operate within safe ranges.

Temperature Transducers

Monitor fuel, lube oil, and cooling water temperatures to prevent overheating or inefficient purification.

Flow Transducers

Measure liquid flow rates in ballast, bilge, and fuel systems to ensure regulatory compliance and balanced operations.

Level Transducers

Track liquid levels in tanks, preventing overfilling and ensuring stability at sea.

Why Transducers Are Critical

- Operational Precision: Accurate readings enable automation systems to make fine-tuned adjustments.

- Safety Assurance: Early detection of irregularities prevents equipment failures.

- Regulatory Compliance: Supports adherence to IMO and MARPOL environmental standards.

- Fuel Efficiency: Optimized separator and pump operations lower fuel consumption.

How Water Valve Blocks and Transducers Work Together

While water valve blocks manage fluid distribution, transducers supply the data necessary for those valves to be adjusted automatically. This creates a closed-loop system where fluid management is continuously optimized.

Example in Practice:

- A separator requires precise water control during self-cleaning cycles.

- The valve block regulates water input and discharge.

- Transducers monitor flow and pressure to ensure the cycle runs smoothly.

- If deviations occur, the automation system adjusts the valve block in real-time.

This synergy leads to:

Reduced manual intervention

More consistent operational results

Greater system longevity

Maridec’s Expertise in Water Valve Blocks and Transducers

At Maridec, we specialize in supplying genuine and compatible spare parts for marine systems worldwide. Our range of water valve blocks, water block assemblies, and precision-engineered transducers are designed to meet the highest industry standards.

What We Offer:

- Spare parts compatible with leading marine brands (Alfa Laval, GEA, Mitsubishi, and more)

- Durable materials built for high-pressure and corrosive marine environments

- Technical support to help operators select the right part for their system

- Fast global shipping to reduce downtime for vessels in operation

Choosing the Right Spare Parts for Your Vessel

When selecting water valve blocks or transducers, consider:

- System Compatibility – Ensure the component fits seamlessly with existing marine equipment.

- Operational Demands – High-contamination environments may require more durable transducers and robust valve blocks.

- Maintenance Strategy – Routine replacement of critical components reduces the risk of unexpected breakdowns.

- Supplier Reliability – Choosing a trusted supplier like Maridec guarantees quality and availability.

The Risks of Using Substandard Components

Cutting costs with substandard or non-genuine spare parts can have serious consequences:

- Increased likelihood of leaks or pressure failures

- Unreliable readings from faulty transducers

- Higher long-term costs due to emergency repairs

- Possible non-compliance with international safety and environmental standards

Investing in quality water valve blocks and transducers is therefore not an expense but a safeguard for uninterrupted vessel operations.

Conclusion

Although small in size, water valve blocks and transducers are essential for maintaining the efficiency, safety, and compliance of marine systems. Their combined role in fluid management and real-time monitoring ensures that vessels operate reliably under demanding conditions.

At Maridec, we provide high-quality spare parts and professional guidance to help ship operators maintain peak performance. By selecting the right components and replacing them at the proper intervals, you safeguard your vessel’s operational reliability and reduce long-term maintenance costs.

Optimize your ship’s efficiency today — Contact Maridec for genuine water valve blocks and transducers tailored to your vessel’s needs.